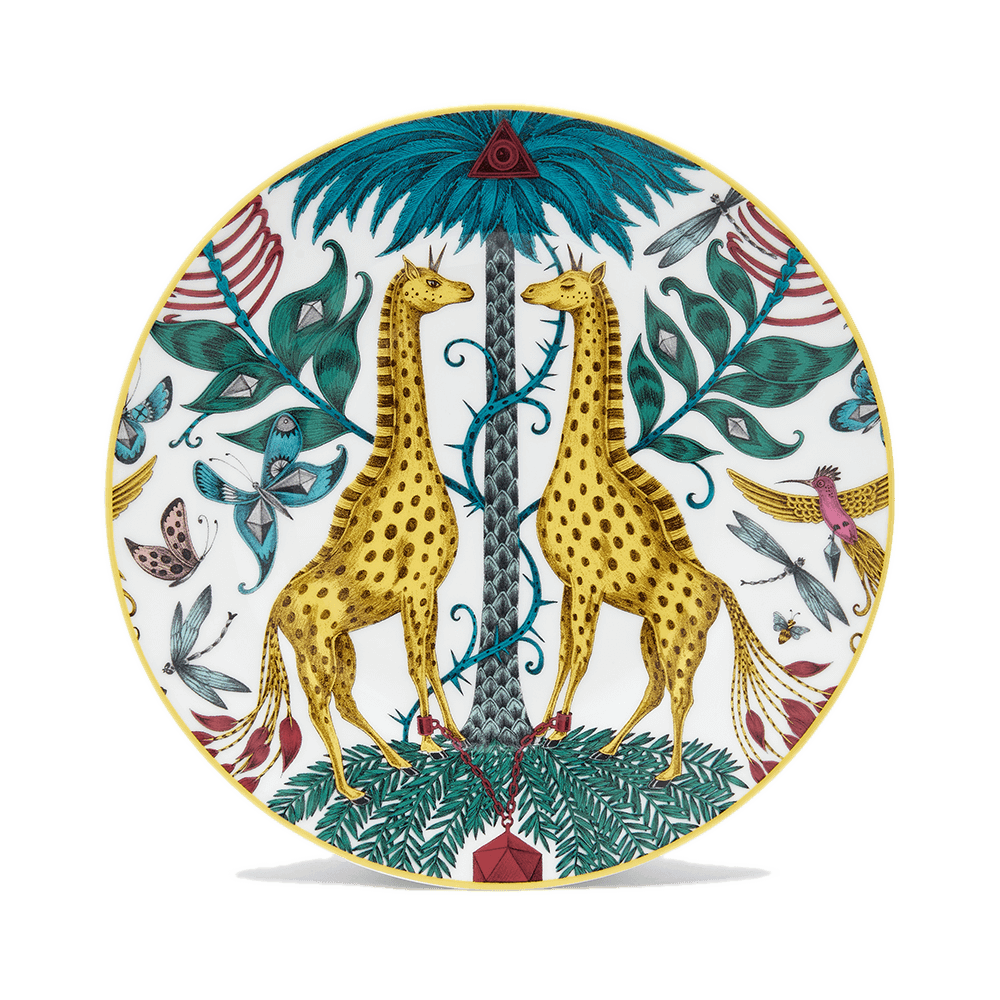

The Making of an EJS Bowl

The Making of an EJS Bowl

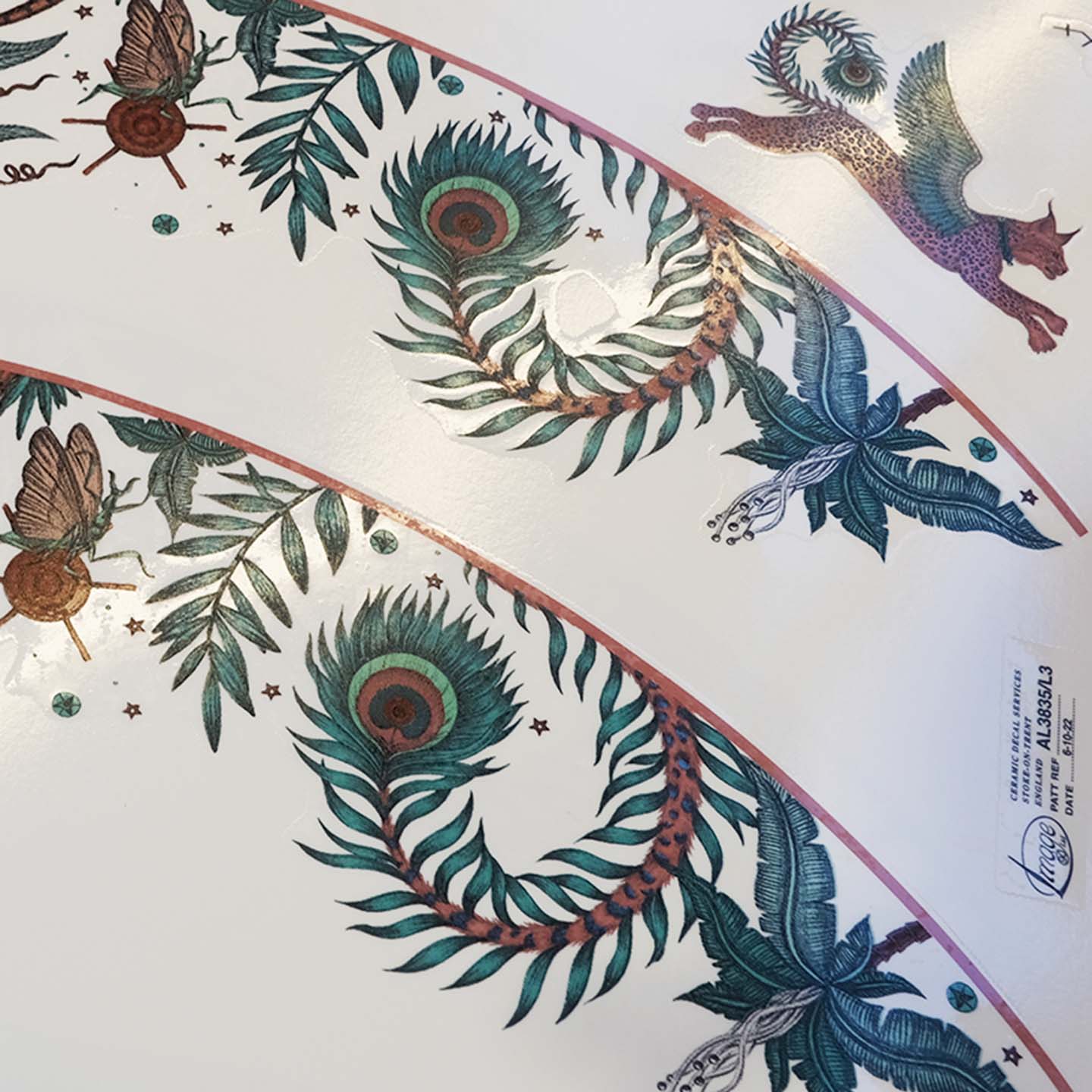

1. Lithographs are printed

Firstly, the lithographs are produced. Twelve separate layers of colour are printed individually onto a special paper, using a silkscreen printing method.

2. Clay filtered and extruded

Then, at our fine china factory, the bone china clay is filtered and extruded to create rolls of clay, ready to be added to the moulds.

3. Moulding

The extruded clay is added to moulds to create the bowl’s shape.

4. Biscuit firing - 1240°c

In this first firing, residual moisture, crystalline-bound water as well as organic components are dissolved and burned from this dried blank. Through this the moulded blank hardens and changes to a stable condition as a fired body.

5. Vibro

The biscuit fired bowls are added to the Vibro machine to clean and polish the ware before glazing (demonstrated with the mugs here).

6. Glazing

A liquid glaze is added to each bowl using a conveyor belt. Taking the bowl through the pink liquid glaze and onwards to a heated chamber to dry.

7. Foot-wiping

Each bowl is foot-wiped to avoid them sticking to the kiln batts during glost firing.

8. Glost firing - 1085°c

During the glost firing (also known as the glaze firing or second firing) process, the glaze melts on the fired body and forms a vitreous, glass-like surface.

9. Lithographs applied

The lithographs are dipped in water which lifts the design from the backing and these are then slid onto the bowl and positioned with the help of a sponge.

10. Final firing - 850°c

11. Quality control and packaging